What is a Clod Crusher in Pneumatic Transport Systems?

A clod crusher in pneumatic transport systems is a device designed to break up clumps or lumps of solid material during pneumatic transport. This equipment ensures that the material flows continuously and evenly through the system, preventing blockages and ensuring efficient transfer. The clod crusher facilitates the reduction of clumps, allowing the material to be transported without interruptions and maintaining the quality of the final product.

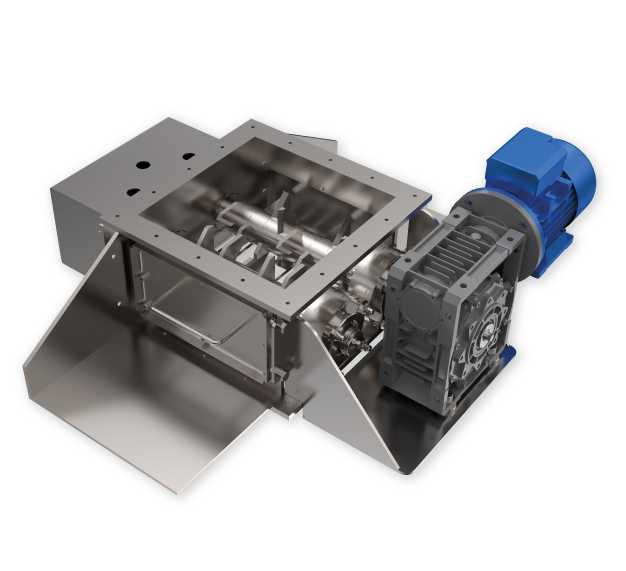

- Manufactured in stainless steel / Carbon steel.

- Possibility of control from the control panel.

- Design flows from 1 ton/h to 20 ton/h (According to requirements).

- Includes motor reducer at 220-440VAC/3Ph/50-60Hz with IP54 motor electrical protection.

- Motor reducer with direct coupling to the clod breaker shaft.

- Design with one or multiple shafts of breaking blades, with power transmission system between shafts.

- Blade speed of 1m/s (from the tip).

- Inlet and discharge connection via flange with a diameter ranging from 300 to 500mm.

- Height of the clod breaker is 350mm.

- Admission of clods up to a maximum of 200mm.

- Clod breaking from 10mm (Those smaller than this size pass through directly).

Types of Clod Crushers

Roller Clod Crushers: Utilize rotating rollers to break up clumps of material. Effective for materials that tend to form hard, compact clumps.

Hammer Clod Crushers: Employ rotating hammers or impacts to disintegrate clumps. Ideal for materials with a high tendency to form clumps.

Blade Clod Crushers: Use blades or cutters to crumble clumps. Suitable for softer or less compact materials.

Vibration Clod Crushers: Use vibrations to break up clumps, facilitating disintegration without damaging the material. Useful for delicate materials.

Impact Clod Crushers: Use impact forces to break up clumps. Effective for very compact and hard materials.

Industries Using Clod Crushers

Clod crushers are utilized in various industries to ensure a consistent and efficient flow of solid materials. Key industries include:

- Food Industry: To break up clumps in ingredients such as sugars, flours, and other food powders.

- Chemical Industry: For handling powders that tend to form clumps during processing.

- Pharmaceutical Industry: To ensure the quality and consistency of active ingredients and excipients in powder form.

- Plastic Industry: For processing resins and other plastic materials that may clump.

- Construction Industry: To break up materials such as cement and sand that can form clumps during storage and transport.

- Mining Industry: For handling powdered minerals that may compact into clumps.

- Recycling Industry: To break up clumps of recyclable materials and facilitate processing.

These devices ensure efficient and safe handling of materials in various stages of production and processing.