Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

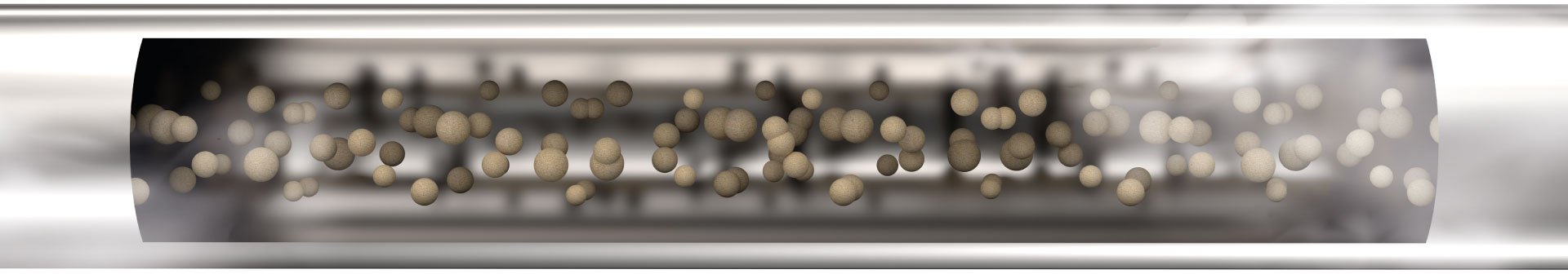

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and Manufacturing

Pneumatic Conveying Systems for the Pharmaceutical Industry

OGA SISTEMVAC S.A.S. actively participates in multiple processes related to the production and manufacturing of pharmaceuticals. We specialize in the movement of solids for feeding equipment such as Double Cone Mixers, V Mixers, Horizontal Mixers, Sieves, Tablet Presses, Encapsulators, Sachet Machines, and Granulators. Our systems guarantee the elimination of segregations in mixtures, minimizing human intervention.

Types of Transport

Our selection of pneumatic conveying systems starts with a rigorous engineering process. We evaluate the physical factors of the raw material to ensure optimal conditions during production, storage, dosing, and mixing in the pharmaceutical industry.

In the pharmaceutical industry, we use Stainless Steel 316 and 316 L due to their anti-corrosive properties. Our transport processes are centrally automated and controlled, complying with strict health and industrial safety regulations. Our design and engineering approach addresses complex challenges, validating the behaviors and properties of compounds in operation. (Types of Transport).

A significant difference between conventional conveyors and OGA systems is that all traditional equipment can only handle a single flow direction, either vertical or horizontal. Our systems, however, can take the product from an origin point and transport it throughout the entire production plant using a single system, combining vertical and horizontal paths interchangeably. This is made possible by employing a single pipeline equipped with long-radius bends to adapt to any process.

This is one of the primary reasons why our clients opt for implementing an OGA system in pursuit of complying with HASS, BPM, and FSSC 22.000 standards. OGA transport systems handle the product within a 100% closed pathway, preventing product contamination from external agents and the pollution of the production environment with the finished product.

Due to OGA pneumatic transport systems generating product movement through gas, mechanical or movable parts are minimal. This results in a high degree of reliability and stability in our equipment, leading to significantly reduced maintenance costs in the systems.

In OGA pneumatic transport systems, there is a single transport pipeline, which allows the implementation of route branches, reaching different and distant destination points throughout the entire production plant. Once a base system is implemented, additional branch routes can be expanded without affecting the initially installed system.

OGA systems feature a control system that can be integrated into the plant’s general software to interact automatically with the entire factory. Alongside this process, variables can be graphed, process traceability can be established, hierarchy levels can be determined for control, automatic maintenance tasks can be performed, remote monitoring via the internet can be facilitated, weight reporting can be conducted, and integration with other process equipment can be achieved.

In OGA pneumatic transport systems, there is a single transport pipeline that allows the implementation of route branches, reaching different and distant destination points throughout the entire production plant. Once a base system is implemented, additional branch routes can be expanded without affecting the initially installed system.