Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Food Industry

Pneumatic Transport Systems in Food Industry have a high degree of applicability in the handling processes of raw materials linked to human and animal consumption. OGA has specialized in designing systems for handling solids, incorporating Good Manufacturing Practices (GMP) for proper implementation in food production processes.

Each development inherently incorporates basic concepts of protection against cross-contamination, accumulation points, ease of equipment cleaning, traceability, and finishes that increasingly meet global industrial demand.

Lean manufacturing

The engineering and design processes of OGA’s Pneumatic Transport Systems in Food Industry contribute to the implementation of Lean Manufacturing, Kaizen, TQM, and 5S models. The progressive development of pneumatic transport systems is established within Industry 4.0, focusing on effectiveness, efficiency, and innovation. These applications enhance resource optimization, equipment usage, and process time without compromising quality or operational benefit.

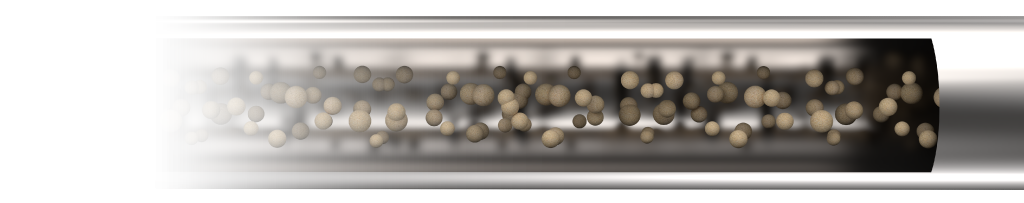

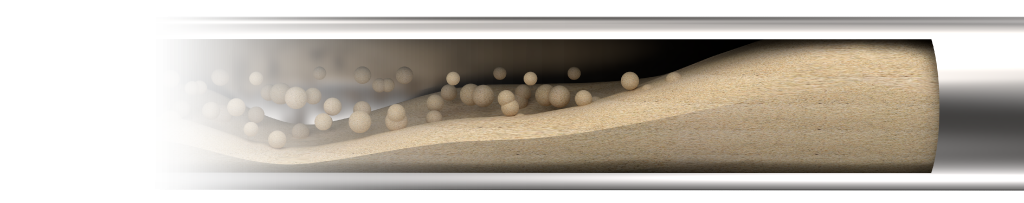

OGA’s pneumatic transport systems can take the product from a starting point and transport it with a single system throughout the production plant, combining vertical and horizontal trajectories. This is achieved using a single pipeline equipped with long-radius bends to adapt to any process, allowing multiple route deviations to serve different and distant destination points.

In addition, there is a commitment to compliance with HACCP, GMP, and FSSC 22,000 regulations, endorsing comprehensive pneumatic transport solutions characterized by the optimal protection of raw materials against external contaminants. These benefits result from applications with minimal implementation of mechanical or mobile components, aiming to minimize wear, process interruptions, and ensure proper maintenance.

- Supply of Bulk Tipping Platforms

- Silos Weighing System

- Inventory Control

- Transportation of Delicate Products

- Transportation of Mixed Products with CV Commitment

- Handling of Big Bags

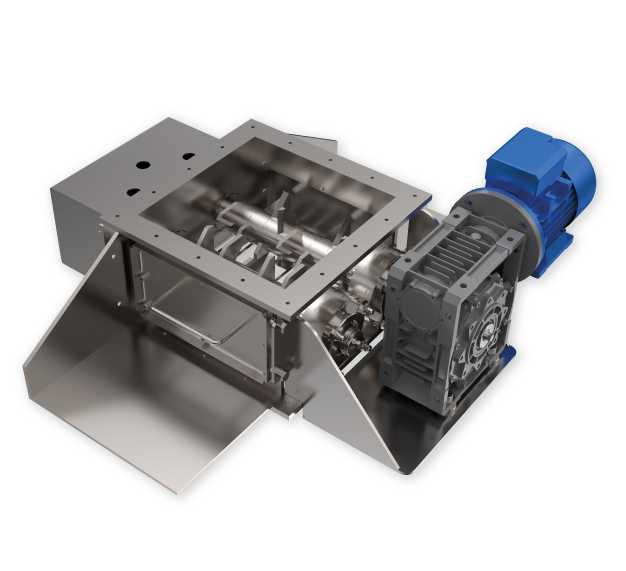

- Solid Dosing to Mixers

- Handling of Highly Abrasive Products

- Material Handling Systems under ATEX Regulations

- Feeding to Storage Silos via Pneumatic Transport

- Storage Silos

- Product Feeding to Process

- Sieving and Classification of Solids

- Transportation of Products Susceptible to Segregation

- Material Handling Systems with ASME Equipment

Pollution Control

One of the most indispensable factors within the Food Industry is the control, prevention, and safety regarding the raw material in the process, protecting it from external contaminating agents. OGA’s Pneumatic Transport Systems in Food Industry undergo a rigorous process to ensure industrial control and prevention, mitigating factors of contaminating pollution in the process.