Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Advanced Solutions in Industrial Pneumatic Conveying Systems and Material Handling

Innovation and Efficiency in Pneumatic Conveying Systems for Various Industries

At OGA SISTEMVAC, we design and manufacture high-quality industrial pneumatic conveying systems applied to multiple industries. These systems facilitate the movement of solid, dry, granular, and powdered raw materials. Whether for industrial automation at specific feeding points or for complex material handling systems through multiple points of origin and destination with automatic control, our products enhance operational efficiency. Our Systems Surpass Bucket Elevators Compared to bucket elevators, pneumatic conveying systems offer a closed, safe, and efficient solution. Additionally, our portfolio includes complementary systems and equipment such as storage silos, custom equipment for magnetic separation, and raw material classification systems. This ensures the purity and quality of the final product.

Get in touch with our advisors

Contact our advisors

Global Experience and Guaranteed Quality

OGA SISTEMVAC provides its expertise worldwide, guaranteeing unparalleled quality and service in industrial pneumatic conveying systems for various industrial sectors.

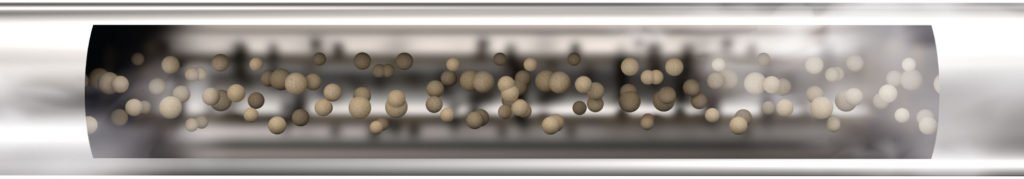

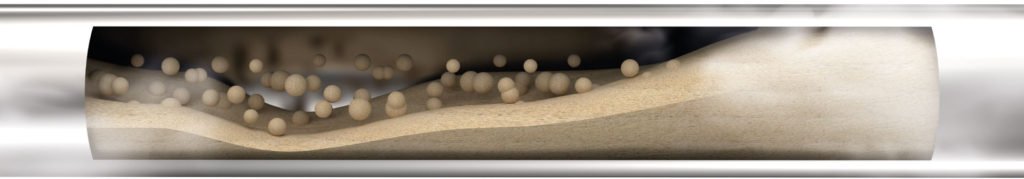

What is Pneumatic Conveying?

Pneumatic conveying is a method in which the movement of materials is achieved through a closed network of pipes, ensuring safe and clean transport. The process begins with air compression, which, when released, creates a stream that carries the materials. This method is especially useful in industries that handle powdered, granular, or finely divided materials.

Advantages of Industrial Pneumatic Conveying

- Efficiency and Speed: This method is fast and efficient for moving large volumes of materials.

- Hygiene and Safety: Being a closed system, it minimizes the risk of contamination of the transported material and improves working conditions by reducing dust dispersion.

- Versatility: It adapts to a wide range of materials and industrial applications.

- Automation: Easily integrates with automatic control systems, enhancing operational efficiency and reducing the need for manual intervention.

Applications

Pneumatic conveying is widely used in various industries, such as:

- Food Industry: For the transport of dry ingredients like flours, sugar, and grains.

- Chemical Industry: In handling powders and granular chemical products.

- Pharmaceutical Industry: For the transfer of powdered pharmaceutical products.

- Plastics Industry: In the handling of resins and plastic pellets.

Key Components of a Pneumatic Conveying System

- Air Compressors for Pneumatic Conveying: Generate the necessary air pressure to move materials.

- Pipes and Ducts for Pneumatic Systems: Form the closed network through which materials are transported.

- Valves and Cyclones in Pneumatic Conveying: Control the flow and separation of materials at different stages of the process.

- Filters for Pneumatic Conveying Systems: Keep the system clean and free of obstructions, ensuring optimal operation.

+3000

Installed systems around the world