Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Pet Food Industry

Pneumatic conveying systems have a high applicability in handling raw materials for the pet food industry. OGA specializes in designing systems that comply with Good Manufacturing Practices (GMP), ensuring their proper implementation in production processes.

Each development incorporates key principles such as protection against cross-contamination, accumulation points, ease of equipment cleaning, protection of finished product against breakage, traceability, and increasingly stringent quality standards demanded by the industry.

Advantages of OGA Pneumatic Conveying Systems

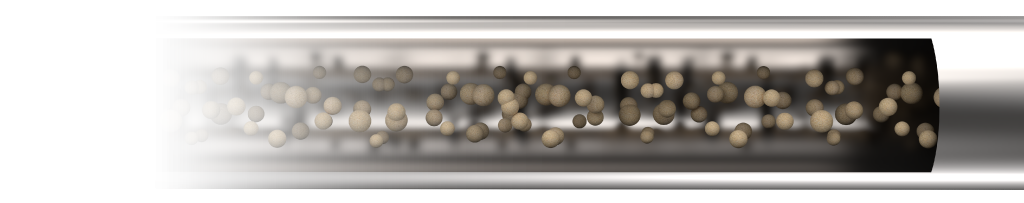

In addition to the extensive portfolio of commercial references, OGA systems can pick up the product from an origin point and transport it with a single system throughout the production plant, combining vertical and horizontal paths interchangeably. This is possible due to the use of a single pipeline equipped with long-radius bends to adapt to any process, allowing multiple route deviations to reach various and distant destination points.

Furthermore, we are committed to complying with HACCP, BPM, and FSSC 22,000 regulations, endorsing comprehensive pneumatic transport solutions for the food industry and rigorous quality guidelines.

Our systems ensure the preservation of the product’s aroma.

Handling of Ingredients in the Animal Industry

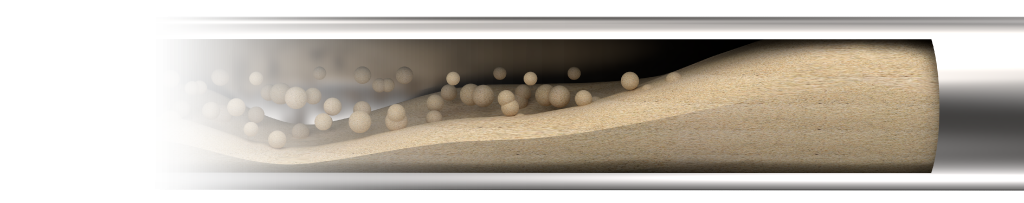

OGA immersion processes have facilitated the handling of multiple materials associated with animal production. These processes demand optimal engineering developments to safeguard product properties and optimize overall production yields according to specific needs. The highlighted ingredients in this production originate from both animal and plant sources, in addition to the use of minerals, vitamins, and amino acids.

Complementarily, there are requirements in the implementation of systems for handling cereals, salts, and sugar, which are essential components of achieving a robust and quality product. The manufacturing process also involves the addition of additives that strengthen the final composition. In this regard, OGA provides comprehensive solutions for handling preservatives, antioxidants, and colorants, whether presented in granular or powder form.

Furthermore, there are complementary processes derived from the main systems, including:

- Supply of Bulk Tipping Platforms

- Silo Weighing System

- Inventory Control

- Transportation of Delicate Products

- Transportation of Mixed Products

- Handling of Big Bags and Sacks

- Solid Dosing to Mixers

- Movement of Highly Abrasive Products

- Material Handling Systems under ATEX Regulations (Upon customer request)

- Feeding into Storage Silos via Pneumatic Transport

- Storage Silos

- Product Feeding into the Process

- Sieving and Classification of Solids

- Transportation of Products Susceptible to Demixing

- Preservation of the structure of Pet Food