Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Specialists in Pneumatic Transport for the PVC Plastic Industry

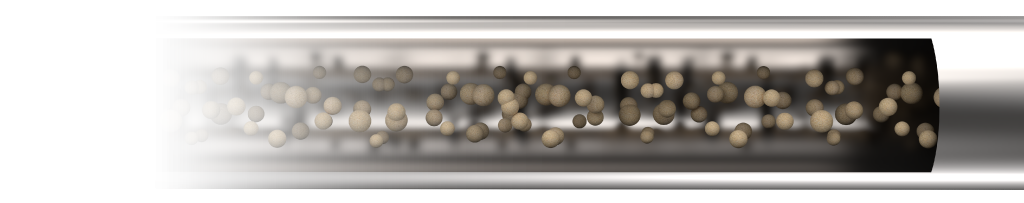

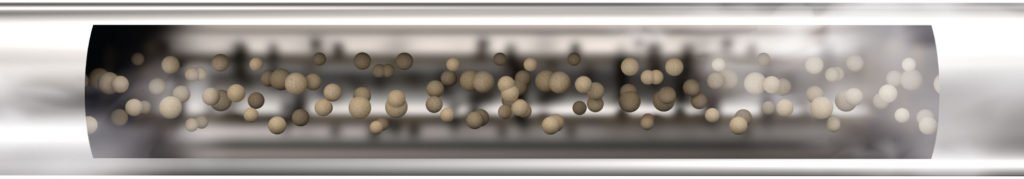

Pneumatic Conveying

Our 26+ years of global experience make us an iconic company in comprehensive pneumatic transport solutions for the PVC plastic industry. Continuous innovation in processes under the Industry 4.0 framework has resulted in multiple applications.

Years of operation worldwide

In the industry, and applications in Central America, the Caribbean, South America, Europe, and the Middle East.

Installed Projects

Installed Projects

At the leading global companies in plastics production.

PVC Plastic Industry Pneumatic Transport Systems

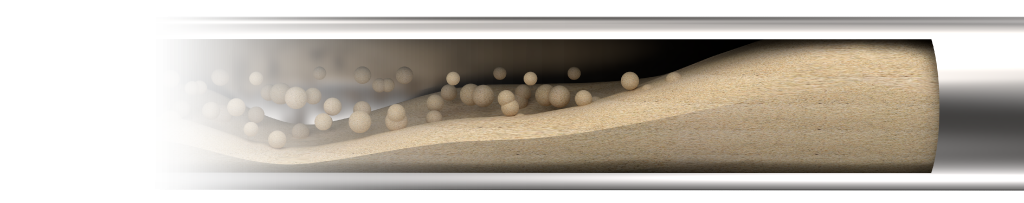

In the PVC plastic and pipe industry, raw materials are typically received in bags, big bags, or bulk. From this point, OGA intervenes in material handling through customized loading and unloading systems tailored to each company. There are two modes of intervention: gradual and direct to the process.

The first involves the discharge and transport of raw materials to storage silos, while the second entails direct transport of raw materials to specific phases of the process, such as mixing towers, extruders, injectors, blowers, coextruders, or other equipment.

Specialists in design and construction of PVC pipe production plants

Complementary Systems

- Bulk unloading systems from containers to silos

- Storage silos for powdered or granular products

- Continuous gravimetric mixing systems in permanent production lines

- Production process control via SCADA software

- Bulk unloading systems from pressurizable hopper cars

- Raw material silo weighing systems

- Sieving systems, granulometric selection of raw materials and final product

- Design of production plants based on solids handling and good manufacturing practices

- Unloading systems from hopper railcars to silos

- Transport systems to daily silos within production plants

- Automatic feeding of production processes from daily silos

- Unloading systems from big bags and transport to storage silos

- Gravimetric dosing system for mixers by batch

- Control and reporting of raw material consumption per production line and/or process

Specialists in design and construction of PVC pipe production plants

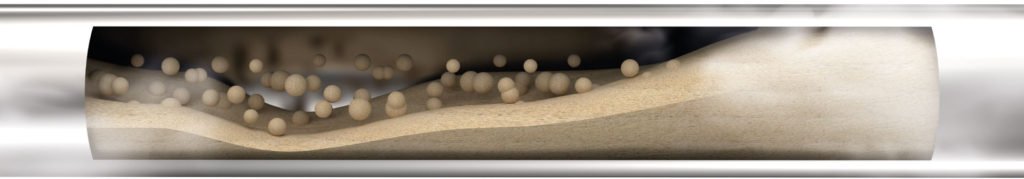

We specialize in designing and constructing PVC pipe production plants. Our developments range from receiving raw materials to delivering the compound to extrusion and injection machines.

OGA systems feature SCADA control models, allowing real-time operation visualization, both locally and remotely. This technology is adaptable to each industry requirement for supervision, inspection, control, and data management.

To meet industry-specific needs, we offer systems for in-line addition of carbonate, addition of pulverized or powdered colorants directly onto the machine, enhancing product physical properties, and reducing production costs.

Types of Installed Systems for the PVC Plastic Industry

- Raw Material Silo Feeding:

- Receipt of raw materials in Hopper Railcars.

- Receipt of raw materials in Hopper Cars.

- Receipt of raw materials in Containers.

- Receipt of raw materials in conventional carriers.

- Receipt of raw materials from Big Bags.

- Receipt of raw materials from 50 and 25kg bags.

- Raw Material Storage Silos.

- Inventory Control in Raw Material Silos by weight.

- Transportation of solid and liquid raw materials to mixing tower.

- Dosing of bulk components into Turbo-Mixers.

- Automatic dosing of micro-components according to recipe into Turbo-Mixer.

- Handling of Double Batch to Cooler.

- Production control leaving mixes via Gravimetric system.

- Sieving of manufactured compound.

- Compound transportation to destination silos and test silos.

- Compound Silos.

- Inventory control of compound silos via gravimetric system.

- Automatic PVC compound transport system to Extrusion lines.

- Automatic transport system of PVC compound, purge, or powder to extrusion line.

- Direct addition system of calcium carbonate onto the extruder via continuous dosing and mixing.