Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Specialists in Pneumatic Transport Systems

Since its inception, OGA has specialized in the design and manufacturing of PNEUMATIC TRANSPORT SYSTEMS, primarily in Dilute Phase and Dense Phase. Our systems range from automating specific feeding points to complex material handling systems with multiple points of origin and/or destination, featuring automatic control for weight, processes, batches, inventory control, bulk handling, big bag handling, etc.

The applications successfully installed with OGA systems nowadays cover flows ranging from 100kg/h to 200 tons/h and distances up to 280 meters, with elevations reaching up to 50 meters.

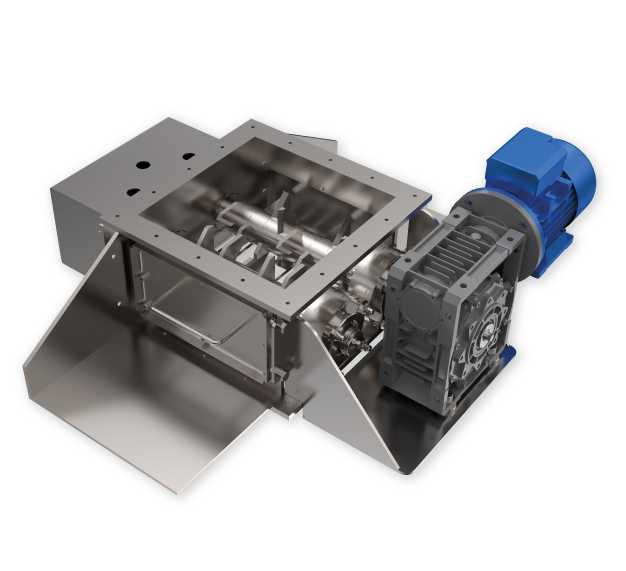

Gravimetric In-Line Dosing Systems

OGA has developed solid handling systems that, in a gravimetric manner, determine the performance of continuous production processes. According to the parameters required by the pre-programmed process, there is continuous addition and mixing of other minor components, which also have weight dosing control. These systems create a control loop that automatically adjusts dosing according to consumption fluctuations in the production process.

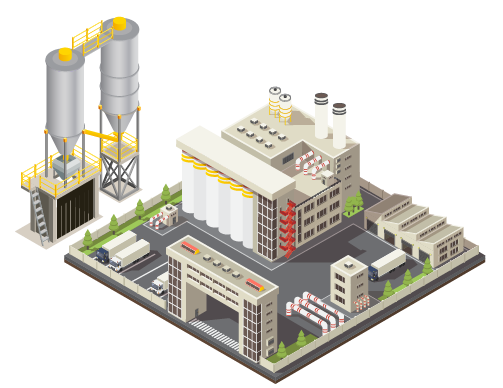

Design and Manufacturing of Industrial Plants

Drawing on decades of experience in the industrial sector and the implementation of multiple production processes, OGA, with its teams, incorporates the development of industrial processes related to the optimization of processes, times, yields, traceability, and their effectiveness. The starting point for all our offerings is a in-depth analysis of the process requirements, and from there, the points of greatest impact are considered in the designed process.

Systems with Supervisory Software

OGA systems feature a control system, which can be integrated into the overall plant software to interact automatically with the entire factory. In conjunction with this process, variables can be graphed, process traceability achieved, hierarchy levels determined for control, automatic maintenance tasks, internet-based supervision, weight reporting, and any integration with other process equipment.

- Pneumatic Conveying of Highly Abrasive Products

- Material Handling Systems under ATEX Regulations

- Feeding to Storage Silos via Pneumatic Conveying

- Storage Silos

- Product Feeding to Process

- Screening and Classification of Solids

- Conveying of Products Susceptible to Segregation

- Material Handling Systems with ASME Equipment

- Supply of Bulk Tipping Platforms

- Silos Weighing System

- Inventory Control

- Pneumatic Conveying of Delicate Products

- Pneumatic Conveying of Blended Products with CV Commitment

- Handling of Big Bags

- Solid Dosing to Mixers

Weighing and Dosing Center for Solids

– Weight measurement in silos for determining raw material inventory, serving as a confirmation model for received products and traceability of material delivered to the production lines.

– Inclusion of recipes via software, where defined weights for the addition of raw materials and moments of discharge into the mixing process are determined. Once the OGA system enters automatic operation, the system doses each component, generating a report with information such as Target Weight, Delivered Weight, Shift Operator, Dosing Time, Batch Manufactured, among other variables included in the control, such as temperature, pressure, etc.

– Generation of reports on plant consumption and performance, with information stored in databases for consultation and future traceability (Measurements, Storage, Comparisons, Mix Components, Process Batches, Operation times on each production line).

OGA develops, according to each need, the specific solid handling system for each application. In the case of handling big bags and bulk materials, we have designed a system tailored to the specific needs of both the raw material supplier and the industrial consumer, applying the following schemes:

- Handling of Big Bags

- Feeding of bulk containers

- Unloading of bulk containers

- Feeding of pressurizable hopper car

- Unloading of pressurizable hopper car

- Bulk unloading with tilting platform