Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Benefits and Advantages of Pneumatic Transport Systems

At the heart of the food, plastics, pharmaceuticals, coffee, powdered milk, cement, and aggregates industries, pneumatic transport is the key to unprecedented handling of solid and granular dry materials.

Why choose it? Here are the unparalleled benefits of pneumatic transport systems that your operation deserves:

1. Speed and Safety in Movement

Speed is essential in any industrial operation. Pneumatic transport systems move materials at an impressive speed, ensuring efficient and seamless handling. Furthermore, the absence of moving parts reduces the risk of accidents, prioritizing safety in your plant.

2. Zero Cross-Contamination

Preserving the integrity of your products is paramount. With pneumatic transport, you can rest assured knowing that handling is done in a closed environment controlled by compressed air. This eliminates any possibility of cross-contamination, keeping the purity of your products intact.

3. Silent and Eco-friendly.

Respect for the environment is essential in modern industry. Pneumatic transport systems operate with minimal noise levels, creating a more comfortable and safer working environment. Moreover, by using compressed air, they do not generate harmful emissions, contributing to a cleaner and more sustainable environment. By employing closed systems and preventing the release of dust and contaminants into the atmosphere, compliance with stricter environmental regulations is achieved, potentially reducing penalties and fines.

4. Minimization of Losses and Spills.

Every gram of material is valuable. With pneumatic transport, handling is precise and controlled, minimizing losses and spills. This translates to higher efficiency and a tangible return on investment.

5. Real-Time Total Control.

Technology advances, and so do we. Our pneumatic transport systems are equipped with advanced real-time controls and monitoring. This provides you with total control over your process, allowing adjustments and optimizations on the spot, without delays or complications.

6. Space Savings:

Pneumatic transport systems take up less physical space compared to other material transportation methods, as they do not require large storage areas or space for mechanical conveyors.

7. Labor Force Reduction:

By automating the material transportation process, the need for manual labor in loading, unloading, and moving materials is reduced, saving labor costs and minimizing the potential for injuries from repetitive physical exertion.

8. Simplified Maintenance and Cleaning:

Pneumatic transport systems tend to require less maintenance than mechanical systems, and their enclosed design facilitates cleaning while preventing the accumulation of residues.

Definition and Types of Pneumatic Transport.

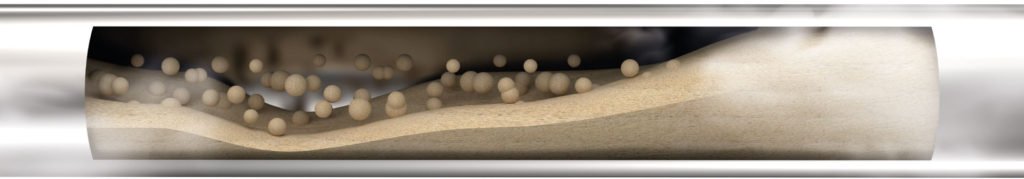

Dense Phase System.

When pneumatic transport requires a high quantity of material in the transport pipeline, it is referred to as dense phase pneumatic transport. This allows for the movement of large quantities of material in short periods, and it is commonly used for conveying materials over significant distances in substantial flows.

It’s important to note that not all materials can be transported in this manner; certain characteristics must be met for dense phase transport to be successful. This type of transport is suitable for highly abrasive materials or pre-mixed blends; due to its low velocity, the chances of segregation are minimal.

A distinctive feature of these systems is that the ratio of air volume to product volume is 90 parts of product to 10 parts of air, with a pressure differential exceeding 4 atm.

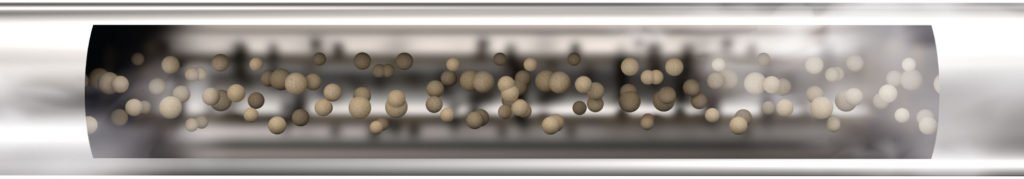

Dilute Phase System.

In this type of transport, there is a large amount of air suspending the material inside the pipeline. Typically, the volume concentrations are on the order of 90 parts of air and 10 parts of product, and the pressure differentials are in line with the installation’s altitude above sea level. However, it can be generalized that the pressure in these systems ranges from 0 to 0.8 atm.

Dilute phase transport systems are characterized by high speeds in the movement of the raw material, a result of the implementation of a high percentage of air compared to the transport material.

Semi-Dense Phase System.

This type of transport combines percentage-wise fundamental aspects of both the Dense Phase and Dilute Phase systems, creating a compact solution with a moderate amount of air in the process, usually employed in vertical transport sections. This type of transport is used in the bulk unloading of pressurizable hopper railcars, typically with pressure differentials ranging from 1 to 2 atm.

Dilute Phase Pressure System.

In this type of transport, a source of air pressure generation is typically used with a maximum differential of 1 atm. Through oil-free rotary lobe blowers, these units introduce a flow of atmospheric air into a transport pipeline, where the product to be transported is introduced by rotary valves that seal the pipeline but allow the entry of the product. The product dissolves in the air stream, achieving its movement from the point of origin to the destination point, which is usually at atmospheric pressure.

Dilute Phase Vacuum System.

The source of motion for this type of system is atmospheric pressure. In this architecture, vacuum is generated through oil-free rotary lobe blowers, which typically create a pressure differential equivalent to 50% of the atmosphere at the installation site. Thus, these systems are highly sensitive to the altitude above sea level where they are implemented.

The basic architecture includes a material source, a transport pipeline, a system for introducing atmospheric air at the starting point of transport, a solid product separator at the end of transport, and a vacuum blower. These systems are typically used for distances shorter than 30 meters and low transport heights.