Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Pneumatic Conveying Systems

Brewing Industry

Over the past 26 years of operation and global coverage, OGA has developed specific solutions for the brewing industry, intervening in the pneumatic transportation processes of solid, granular, and powder raw materials that integrate the production phases of beer.

In its production, OGA emphasizes pneumatic transport solutions for handling barley, wheat, wheat germ, sugar, malt, and starch within the plant. All processes and equipment supplied by OGA are designed under the Good Manufacturing Practices (GMP) factor for solids handling within production models.

Pollution Control

One of the most essential factors in the brewing industry focuses on controlling, preventing, and ensuring the safety of raw materials in the process, protecting them from external contaminating agents.

OGA’s Pneumatic Conveying Systems undergo a rigorous guarantee process of industrial control and prevention, completely avoiding contaminating pollution factors during the pneumatic transport process, in compliance with international standards.

Benefits of OGA Transport Systems

Brewing Industry

Applications executed in major beer production facilities are found in Central America, the Caribbean, and South America. These are characterized by minimal implementation of mechanical or mobile components, ensuring low wear and tear on equipment, avoiding unwanted interruptions in the process, and an efficient preventive maintenance model in the systems.

A significant difference between conventional conveyors and OGA SYSTEMS is that conventional equipment can only handle a single flow direction, either vertical or horizontal in one axis. Our systems can take the product from an origin point and transport it with a single system throughout the production plant, combining vertical and horizontal paths interchangeably due to the use of a single pipe equipped with long-radius curves to adapt to any process.

This is one of the main reasons why our clients have chosen to implement our systems in pursuit of compliance with HACCP, GMP, and FSSC 22,000 standards. OGA transport systems handle the product in a 100% closed pathway, preventing contamination of the product with external agents and environmental contamination with the finished product.

Since OGA PNEUMATIC TRANSPORT SYSTEMS move the product with a gas, mechanical or mobile parts are minimal. This results in a high degree of reliability and stability in our equipment, causing very low maintenance costs for each OGA system.

In OGA PNEUMATIC TRANSPORT SYSTEMS, there is a single transport pipe, allowing the implementation of diversion routes, reaching different and distant destination points throughout the production plant. Once a base system is implemented, derivation routes can be expanded without affecting the initially installed system.

OGA systems come with a control system that can be integrated into the plant’s general SOFTWARE to interact automatically with the entire factory. This process includes graphing variables, process traceability, determination of hierarchy levels for control, automatic maintenance tasks, internet-based supervision, weight reporting, and any integration with other process equipment.

At OGA, each TRANSPORT system is a unique design tailored to each particular application. Multiple variables are combined in general to ensure that each project meets the needs of each user.

Complementary Systems

Bulk unloading systems from containers to silos

Storage silos for powdered or granular products

Production process control via SCADA software

Bulk unloading systems from pressurized hopper cars

Raw material silo weighing systems

Sieving, granulometric selection of raw material and final product

Design of production plants based on solids handling and good practices

Transport systems to daily silos inside production plants

Automatic feeding of production processes from storage silos.

Big bag unloading systems and transport to storage silos

Control and reporting of raw material consumption per production line or process

Supply of bulk tipping platforms

Inventory control

Pneumatic transport of delicate products

Handling of big bags, bags, and boxes

Product feeding to the process

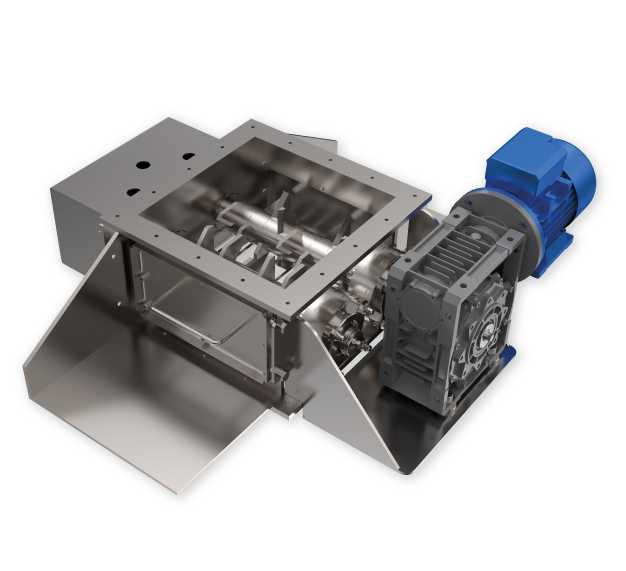

Dry-mode feeding of mixers

Sieving and classification of solids