Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of tailor-made systems for your industry, with global coverage.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Design and manufacturing of pneumatic transport systems applied to multiple industries.

Confectionery and Chocolate Industry

Pneumatic Conveying Systems

The applications executed in the confectionery and chocolate industry affirm our expertise in the comprehensive development of pneumatic conveying systems, where we handle raw materials such as (Flour, Chocolate, Sugar, Citric Acid, Colorants, Sweeteners, Stabilizers, Edulcorants, Cocoa, Panela, Sorbitol, among others). This is done according to the independent model of each producing company.

OGA systems are designed and manufactured under Good Manufacturing Practices (GMP), serving as a resource for secure, cost-effective, and successful implementations. Each development inherently embodies the basic concepts of protection against cross-contamination, accumulation points, ease of equipment cleaning, traceability, and increasingly stringent finishes aligned with industrial demands.

Pollution Control

One of the most essential factors within the coffee industry focuses on controlling, preventing, and ensuring the safety of the raw material in the process, protecting it from external contaminating agents. OGA Pneumatic Conveying Systems undergo a rigorous process to guarantee industrial control and prevention, effectively avoiding contaminating pollution factors in the pneumatic transport process, complying with international regulations.

Gum (Chewing Gum)

Intrinsically embedded are the specific processes in handling and manufacturing chewing gum, where OGA offers specific solutions that maximize care and quality during the production phases.

- Minimal breakage of chewing gum coating

- Zero degradation of chewing gum coating

- Preservation of the product’s characteristic geometry

- No impact on the gum fillings

- No cross-contamination by transfer between differently colored gums

- Powdered gums without segregation.

OGA optimizes the processes of transportation, feeding, storage, and unloading in mixers, pre-extruders, extruders, and the packaging phase.

Advantages of OGA Pneumatic Transport Systems

In addition to the extensive portfolio of commercial references, OGA systems can pick up the product from an origin point and transport it with a single system throughout the production plant, combining vertical and horizontal paths interchangeably. This is possible due to the use of a single pipeline equipped with long-radius bends to adapt to any process, allowing multiple route deviations to reach various and distant destination points. Furthermore, OGA systems are committed to complying with HACCP, BPM, and FSSC 22,000 regulations.

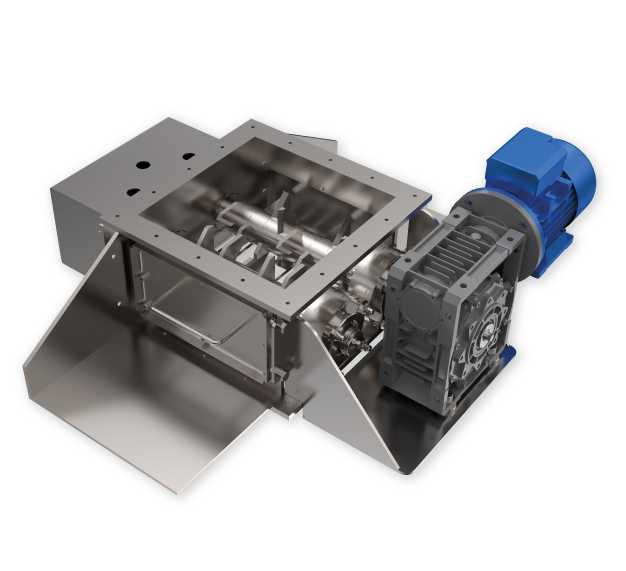

OGA Complementary Equipment

Additionally, there are complementary processes derived from the main systems, including:

- Silo Weighing System

- Inventory Control

- Delicate Product Transportation

- Handling of Big Bags or Sacks

- Solid Dosing

- Movement of Highly Abrasive Products

- Material Handling Systems under ATEX Regulations (Upon customer request)

- Feeding into Storage Silos via Pneumatic Transport

- Storage Silos

- Product Feeding into the Process

- Sieving, Solid Classification, and Product Cleaning

- Transportation of Products Susceptible to Demixing

- Material Handling Systems with ASME Equipment (Upon customer request).